Some Great Benefits Of Making Sugarcane Charcoal From Bagasse

The process of refining sugar involves cutting up sugarcane into small pieces and then crushing it to extract the juice. After the process is over, the leftover pulp in the sugarcane, which is called bagasse, is often discarded. The sugarcane bagasse charcoal machine make charcoal with these waste sugarcane bagasse.

Imagine just how much less organic waste would be a consequence of the sugar making process in case the sugarcane pulp might be put to some type of use as an alternative to being disposed of. Because it turns out, it can. There are actually machines in the marketplace that are designed for making sugarcane charcoal from bagasse. The resulting briquettes can be used fuel for a variety of different purposes, making it a wonderful way to reuse something that otherwise might have been discarded.

The process of making charcoal from bagasse is comparatively simple. First, the bagasse needs to be thoroughly dried out. Biochar production technology Beston posess is advanced. Dependant upon the complexity of your charcoal making operation, this can be done in several alternative methods. For smaller operations, the bagasse is normally laid out in the sunshine to dry for a few weeks. This can be a simple solution that gives achievement without requiring any other power.

Larger charcoal manufacturers might need to process the bagasse more rapidly. Additionally, they usually take care of a significantly larger volume. Because of this, they generally dry the bagasse in specialized machines that assist eliminate the moisture as an alternative to allowing it to dry naturally in the sun. This accelerates the drying efforts and enables them to produce the finished charcoal briquettes much more quickly.

After the bagasse is dry, this will make it transferred to a specialized kiln where it can be heated to your high temperature. There is certainly almost no oxygen within the chamber. This turns the bagasse into a black charcoal powder.

Right after the carbonization process is done, the powder will be formed into briquettes using a specialized machine. It is almost always then put into bags in order that it may be transported to stores and sold towards the public.

There are a variety of benefits connected with making charcoal sugarcane from bagasse. To begin with, it helps minimize the quantity of organic waste that results from the sugar making process. Rather than throwing the bagasse away, it might be put to use again.

Traditional charcoal is made of wood. Unfortunately, trees take a very long time to develop. They are also in short supply in a few parts on the planet.

Sugarcane, on the flip side, grows considerably more quickly. Because of this, this is a considerably more eco-friendly source for producing charcoal.

Finally, following the charcoal briquettes happen to be used, the resulting ash might be included with the soil being a fertilizer, helping new plants to cultivate. Ash from biochar like sugarcane bagasse briquettes might help enrich the soil, which makes it a lot more competent at supporting plant life.

Transforming bagasse into charcoal briquettes is a wonderful way to give a item that would otherwise be discarded new life. As opposed to throwing the bagasse away, it could be transformed into an eco-friendly fuel source that can help save trees and reduces society's reliance upon standard fuels. Get environmental-friendly machine on https://carbonationmachine.net/.

|

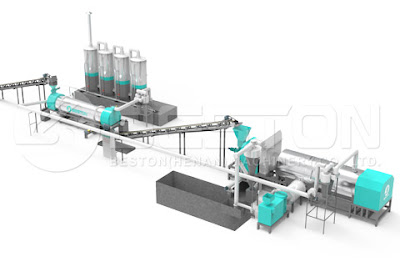

| Sugarcane Bagasse Charcoal Production Plant for Sale |

The process of making charcoal from bagasse is comparatively simple. First, the bagasse needs to be thoroughly dried out. Biochar production technology Beston posess is advanced. Dependant upon the complexity of your charcoal making operation, this can be done in several alternative methods. For smaller operations, the bagasse is normally laid out in the sunshine to dry for a few weeks. This can be a simple solution that gives achievement without requiring any other power.

Larger charcoal manufacturers might need to process the bagasse more rapidly. Additionally, they usually take care of a significantly larger volume. Because of this, they generally dry the bagasse in specialized machines that assist eliminate the moisture as an alternative to allowing it to dry naturally in the sun. This accelerates the drying efforts and enables them to produce the finished charcoal briquettes much more quickly.

After the bagasse is dry, this will make it transferred to a specialized kiln where it can be heated to your high temperature. There is certainly almost no oxygen within the chamber. This turns the bagasse into a black charcoal powder.

Right after the carbonization process is done, the powder will be formed into briquettes using a specialized machine. It is almost always then put into bags in order that it may be transported to stores and sold towards the public.

Traditional charcoal is made of wood. Unfortunately, trees take a very long time to develop. They are also in short supply in a few parts on the planet.

Sugarcane, on the flip side, grows considerably more quickly. Because of this, this is a considerably more eco-friendly source for producing charcoal.

Finally, following the charcoal briquettes happen to be used, the resulting ash might be included with the soil being a fertilizer, helping new plants to cultivate. Ash from biochar like sugarcane bagasse briquettes might help enrich the soil, which makes it a lot more competent at supporting plant life.

Transforming bagasse into charcoal briquettes is a wonderful way to give a item that would otherwise be discarded new life. As opposed to throwing the bagasse away, it could be transformed into an eco-friendly fuel source that can help save trees and reduces society's reliance upon standard fuels. Get environmental-friendly machine on https://carbonationmachine.net/.

Comments

Post a Comment